Continuity in design, manufacturing and production engineering of high precision complex components for analytical and life science applications.

We add value by specializing in continuity of design, manufacturing and production engineering of high precision complex components and products for analytical and life science applications. We understand the accuracy and chemical compatibility challenges with materials used in chromatography and mass spectrometry.

Our focus is on very small to medium sized components down to 0.2 mm diameter, manufactured to extremely tight tolerances. Micron accuracy is achieved through unique production methods and specialized work holding apparatus.

Whether simple or intricate, we have the knowledge, sophisticated equipment and over 50 years of engineering and manufacturing experience to produce the appropriate solution for your project.

Learn more about our other technical capabilities.

Capabilities

- ◄CNC complex machining

-

CNC multi-axis machining

- Multiple axis CNC machines - up to 11-axis with twin spindle (C axis) and twin turret configuration.

- Component transfer within the machine between different operations maintains part concentricity and feature integrity (removes manual handling).

- Motion control (automatic program optimization for sequential and synchronized machining).

- External tool setting, enabling advance preparation and quick change between operations.

- Conventional turning and milling (4-axis, rotary).

- Offset face drilling down to 0.4 mm (specified hole position, not just the center).

- ◄Milling and drilling

-

- Compact design

- 15,000 RPM (precision collet)

- Synchronized tapping at 6,000 RPM

- 2.3 second tool change (chip to chip)

- Full conversational programming

- 4 axis (rotary table)

- 3D machining

- Rapid traverse 56 meters per minute (minimizes non-productive time)

- ◄Specialist grinding

-

CNC cylindrical (internal, external, and face grinding)

- Air purged linear scales and digital readout for wheel head angular adjustment for improved accuracy

- Minimum programmable increment of 0.001 mm

(1 µm) - Component diameter from

5 mm to 300 mm - Roundness and parallelism down to 0.002 mm (2 µm)

Centerless (CNC and conventional)

- Components ground from 0.2 mm to 35 mm in diameter, up to 3 m long

- Sub-micron increment adjustment - we achieve tolerances down to

±0.002 mm (2 µm), using unique jigging methods

- ◄Precision laser cutting and welding

-

CNC Nd:YAG laser production

CNC Nd:YAG laser production- CNC controlled precision laser cutting and welding with controlled depth

- 4-axis platform for complex operations, plus secondary rotary attachment for welding

- Single-pulse and percussion precision micro drilling down to 0.06 mm

(60 µm) - Cut grooves down to 0.05 mm (50 µm)

- ◄Diffusion bonding

-

Diffusion bonding

- Bonding multiple layers into one, retaining properties of the base metals

- ◄Lapping and finishing

-

Lapping

Lapping- Produces optically flat surfaces within 0.003 mm

(3 µm) - Fully controllable electronic abrasive dispensing system

- Lap components up to 180 mm diameter

Finishing

- Can produce optically flat surfaces with high precision surface finishes

- Laser marking

- Ultrasonic cleaning

- Vibratory deburring

- Surface grinding

- Sandblasting

- Cratex deburring, cleaning and polishing

- Produces optically flat surfaces within 0.003 mm

- ◄Metal surface treatments

-

Metal treatments

- Hardening

- Anodizing (range of colors)

- Plating (e.g. electroless nickel, chrome)

- Coatings (e.g. titanium nitride)

- Stress relieving of raw materials to ensure consistent results during manufacturing

- ◄Materials knowledge and production expertise

-

Material selection

Production using a wide range of materials:

- Acetal

- Acrylic

- Aluminum

- Borosilicate glass^

- Brass

- Copper

- Delrin

- Graphite Vespel®

- Ekonol

- High tensile steel

- HDPE

- Nylon

- Platinum^

- PTFE

- PEEK (polyetheretherketone)

- Polycarbonate

- Polypropylene (PP)

- Polyvinylchloride (PVC)

- Silicone rubber/PTFE

- Stainless steel

- Torlon

- UHMWPE

^grinding only

Tool optimization

- Optimization of cutting tools (machinery).

- Micron accuracy is achieved through unique production methods, customizing tools and specialized work holding apparatus.

- In-house custom tool production for specific projects.

- CNC programming expertise to ensure efficient tool setup and consistent output.

- ◄Development and design experience

-

Development and design

- Production and R&D engineering expertise.

- Solid Edge CAD software suite.

- CAD-Cam software specifically tailored for programming and CNC code generation for complex components.

- Dedicated CNC lathe for R&D projects.

- Optimizing design early in project development by working closely with partners, to assess feasibility of commercial product.

Mass production

Process development for scalable production quantities (taking small volume or one-off prototypes to create reproducible results at a high volume).

- ◄Quality assurance

-

CMM vision probe metrology

Coordinate Measuring Machine (CMM) with probe and vision measurement

- Programmable zoom lens and macros.

- Docking station for auto probe changing (reduce non-productive processing time).

- Sophisticated metrology software.

- 0.5 µm resolution X, Y, and Z scales.

- TP200 electronic probe system (more accurate than mechanical probe).

- Customized metrology reports.

Laser metrology

- Laser measurement (non-contact) inspection of ground metal components, and items made of PTFE or other soft materials.

- Reading accuracy to

0.0001 mm (1 µm).

Case studies

Needles

Custom needles for manual applications and diagnostic instrumentation.

- Specializing in grinding micro precision components down to 0.2 mm diameter

- We achieve tolerances down to ±0.002 mm (2 µm), using specialized work holding jigs to grind intricate shapes using laser measurement to control the specifications.

- The needle provides the piercing action and flow path for liquid or gas samples from the syringe to a vial or an injection port of an instrument.

- The tip of the needle is a critical feature that impacts the functionality of the finished syringe and ultimately the resulting preparation or analysis of test samples.

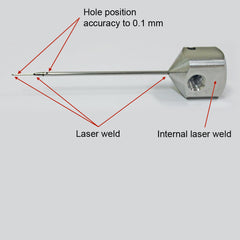

Probes

Custom probes for applications in analytical and diagnostic instrumentation.

- Consists of CNC machined components, specialized tip grinding techniques and precision laser welding.

- Positional accuracy (0.1 mm) of the holes are critical for alignment purposes.

- Special inert coating process ensures contamination free product.

- Unique processes and design to minimize “coring”.

- Surface finishing techniques ensuring smooth transition from tip to block resulting in reduced penetration forces.

Frames

Custom precision frames for integration into instruments requiring optical flatness.

- This particular MS grid frame was ground within 0.017 mm flatness (verified by CMM probe measurement).

- Component cross-section and thickness required a different manufacturing approach to achieve flatness specification.

- Frames were measured removed, re‐measured in the clamped state then measured (twice) in the free state.

- Force applied to the clamping screws = 0.3 Nm

Flanges

Custom precision flanges for mounting parts and devices within instruments.

- This flange is used for mounting Time of Flight (TOF) Electron Multipliers. It is necessary to mount the detector so that its ion impact surface is accurately aligned with the instrument’s nominal ion arrival plane.

- Proprietary work holding devices were used to ensure critical features and dimensional specifications were accurately machined. The oblique interpolated “D” shape holes, true position holes, trapezoid shape and sealing surfaces are critical as they impact performance of the Multiplier and ultimately the end analysis results.

- The main features were machined in one operation.

Dynodes for mass spectrometry

Dynodes are complex parts requiring multiple machining operations, precise dimensional accuracy and unique design features.

- We manufacture accurate components for discrete-dynode electron multipliers which are used to detect ions in mass spectrometers. This detector is critical to an instrument’s sensitivity and performance.

- Unique dynode shapes increase active surface area for maximum performance, stability and extend operating life.

- We produce this particular dynode in one operation, to tolerances down to ±0.02 mm (20 µm). Uniform mounting holes ensure it can be fixed to precise locations within the detector.

- The bowl shape and surface finish are critical features both dimensionally and optically - they directly impact the instrument’s functional stability and accuracy.

Multi-channel device (MCD)

Trajan manufactures highly complex gas chromatography multi-channel devices (MCD) using CNC multi-axis machining, offset face drilling (down to 0.4 mm), CNC Nd:YAG laser welding and cutting (with shims down to 75 µm) and lapping (to a flatness within 0.005 µm). The device operates at pressures greater than 25,000 psi (170,000 kPa) and temperatures up to 420°C.