Trajan offers a complete technical service from concept design, production, treatments, finishing, assembly, quality assurance and packaging to worldwide logistics.

Trajan offers a complete technical service from concept design, production, treatments, finishing, assembly, quality assurance and packaging to worldwide logistics.

We deliver enhanced value to our global network of customers as a technical and commercial collaboration partner with extensive facilities.

- ◄Glass drawing and fabrication

-

Precision glass fabrication and surface treatments.

We are a world leader in syringes and injection port consumables, with over 50 years glass forming expertise creating products for leading companies in analytical science. We have an intimate knowledge of silica properties and surface treatments for analytical applications.

- Glass forming and extruding expertise – capillaries, microstructures, optical fibers

- Manufacture of precision bore glass cylinders

- Materials selection and production expertise for scientific analysis

- Glass doping with rare earth elements by MCVD

- Inert glass surface treatments

- Glass materials engineering expertise - tapering, splicing, cutting and cleaving

- Glass surface, fiber and capillary modification

- Assembling glass and metals in various configurations

- Semi-automated manufacturing

Examples:

- ◄Optical glass and photonics sensing technologies

-

Optical glass development, fabrication and characterization of high quality specialty glass for high non-linearity applications, waveguide use and laser applications.

- Critical glass component fabrication and characterization

- Photonics based fiber sensors and light measurements

- Development and delivery of multi-structured preforms for fiber producers

- Production of specialty high performance optical and/or ultra high temperature resistant fibers

Example:

Ultra-High Temperature Sensor (uHTS) - The ultra-high temperature sensor (uHTS) is an optical fibre sensor (OFS) for measuring ultra-high temperature in extreme environments. Control of processes operating at ultra-high temperature (>900°C) or extreme environments is challenging without access to meaningful and reliable data. Many technologies currently available for ultra-high temperature are prone to corrosion or electromagnetic interference which impact the reliability of data and the longevity of measurement. The uHTS is manufactured as a product which provides meaningful data for the understanding and control of temperature in environments where this has not previously been possible.

- ◄Chemical synthesis and separation solutions

-

Specialized chemistries, polymer synthesis, coatings and expertise in materials science and chemical interactions for fabrication of platform components.

We have expertise in the properties and interactions of materials and chemicals, creating specialized coatings for a range of applications, phases for accurate and reproducible results and unique chemical and polymer fabrication techniques.

- Custom stationary phase synthesis

- Biocompatible/inert separation solutions

- Solid Phase Extraction (SPE) and MEPS® (microSPE)

- Protein/peptide separation solutions

- Chemical surface treatments

- Pathology stains and reagents

Examples:

- ◄Precision machining and design engineering

-

Continuity in design, manufacturing and production engineering of high precision complex components for analytical and life science applications.

We add value by specializing in continuity of design, manufacturing and production engineering of high precision complex components and products for analytical and life science applications. We understand the accuracy and chemical compatibility challenges with materials used in chromatography and mass spectrometry.

Our focus is on very small to medium sized components down to 0.2 mm diameter, manufactured to extremely tight tolerances. Micron accuracy is achieved through unique production methods and specialized work holding apparatus.

Whether simple or intricate, we have the knowledge, sophisticated equipment and over 50 years of engineering and manufacturing experience to produce the appropriate solution for your project.

- CNC complex machining

- Milling and drilling

- Specialist grinding

- Precision laser cutting and welding

- Diffusion bonding

- Lapping and finishing

- Metal surface treatments

- Materials knowledge and production expertise

- Development and design experience

- Quality assurance

Case studies

Needles

Custom needles for manual applications and diagnostic instrumentation.

- Specializing in grinding micro precision components down to 0.2 mm diameter

- We achieve tolerances down to ±0.002 mm (2 µm), using specialized work holding jigs to grind intricate shapes using laser measurement to control the specifications.

- The needle provides the piercing action and flow path for liquid or gas samples from the syringe to a vial or an injection port of an instrument.

- The tip of the needle is a critical feature that impacts the functionality of the finished syringe and ultimately the resulting preparation or analysis of test samples.

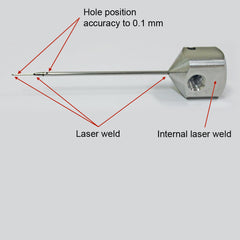

Probes

Custom probes for applications in analytical and diagnostic instrumentation.

- Consists of CNC machined components, specialized tip grinding techniques and precision laser welding.

- Positional accuracy (0.1 mm) of the holes are critical for alignment purposes.

- Special inert coating process ensures contamination free product.

- Unique processes and design to minimize “coring”.

- Surface finishing techniques ensuring smooth transition from tip to block resulting in reduced penetration forces.

Frames

Custom precision frames for integration into instruments requiring optical flatness.

- This particular MS grid frame was ground within 0.017 mm flatness (verified by CMM probe measurement).

- Component cross-section and thickness required a different manufacturing approach to achieve flatness specification.

- Frames were measured removed, re‐measured in the clamped state then measured (twice) in the free state.

- Force applied to the clamping screws = 0.3 Nm

Flanges

Custom precision flanges for mounting parts and devices within instruments.

- This flange is used for mounting Time of Flight (TOF) Electron Multipliers. It is necessary to mount the detector so that its ion impact surface is accurately aligned with the instrument’s nominal ion arrival plane.

- Proprietary work holding devices were used to ensure critical features and dimensional specifications were accurately machined. The oblique interpolated “D” shape holes, true position holes, trapezoid shape and sealing surfaces are critical as they impact performance of the Multiplier and ultimately the end analysis results.

- The main features were machined in one operation.

Dynodes for mass spectrometry

Dynodes are complex parts requiring multiple machining operations, precise dimensional accuracy and unique design features.

- We manufacture accurate components for discrete-dynode electron multipliers which are used to detect ions in mass spectrometers. This detector is critical to an instrument’s sensitivity and performance.

- Unique dynode shapes increase active surface area for maximum performance, stability and extend operating life.

- We produce this particular dynode in one operation, to tolerances down to ±0.02 mm (20 µm). Uniform mounting holes ensure it can be fixed to precise locations within the detector.

- The bowl shape and surface finish are critical features both dimensionally and optically - they directly impact the instrument’s functional stability and accuracy.

Multi-channel device (MCD)

Trajan manufactures highly complex gas chromatography multi-channel devices (MCD) using CNC multi-axis machining, offset face drilling (down to 0.4 mm), CNC Nd:YAG laser welding and cutting (with shims down to 75 µm) and lapping (to a flatness within 0.005 µm). The device operates at pressures greater than 25,000 psi (170,000 kPa) and temperatures up to 420°C.

- ◄Automation and workflow integration

-

We've been helping our customers find the right solution for their laboratories for over 26 years, with our workflow optimization expertise in sample preparation and capability integration.

Generating complete automated sample-centric workflow solutions through custom hardware and software modules to address real-world laboratory challenges.

We add value with higher efficiency, error reduction and tighter specifications for your analytical results. Wherever there is a repetitive process for sample collection, sample preparation or delivery to analytical instrument - automation can reduce or eliminate many possible error sources.

The biggest challenges for most of our customers is precise, fast and reliable sample prep before loading a sample onto an analyzer or detector system. We analyze the process and customize a new solution.

- ◄Microfluidic solutions

-

World leading provider of micro and nanoscale fluidic solutions for the analytical and life science instrument markets. We are the only company in the world that manufactures Fused Silica Tubing, and emitter tips for mass spectrometry applications.

- Sophisticated Fused Silica Tubing production facilities and thermoplastic PEEK tubing extrusion

- GLT™ (Glass Lined Tubing) and PEEKsil® tubing

- Nano bore tubing for analytical and medical devices

- Microfluidic and microchannel devices for multidimensional analyses

- Tubing for a range applications including high throughput DNA sequencing, dispensing pump systems and other scientific instruments

- ◄Device development

-

Development of devices for analytical and medical applications, with a focus on portability, affordability and miniaturization.

- Microsampling and dried blood spotting medical devices

- Precision and accurate liquid handling devices

- Manufacture of critical components for devices and instruments

Examples:

- ◄Pathology consumable manufacturing and supply

-

Microscope slides

Our expertise in glass and surface treatments puts us in a unique position to influence the continuous improvement of global diagnostic practices via the supply of quality and enhanced microscope slides.

The team at Trajan will help you in identifying the best slides and solutions from our range to suit your workflow and applications. Custom made formats and slides can be made to order.

Pathology supply

Trajan has been supplying Australian laboratories for more than 30 years, with a focus on understanding operational challenges and working together to explore tailored supply arrangements. Our ongoing commitment is to provide personalized and knowledgeable customer service, and quality laboratory products.

Contact us or one of our pathology authorized distributors in our global network.

- ◄Complete kitting and packing solutions

-

Analytical kits

We offer unique tubing and connections that link technologies for optimal results in complex configurations; creating convenient kits for a range of applications.

- ◄Quality and compliance

-

Trajan has a dedicated quality and continuous improvement team.

Trajan offers a complete technical service from concept design, production, treatments, finishing, assembly, quality assurance and packaging to worldwide logistics.

Trajan offers a complete technical service from concept design, production, treatments, finishing, assembly, quality assurance and packaging to worldwide logistics.