The world's understanding of glass has grown exceptionally within the last two centuries followed by ground-breaking innovations. Advances in glass science and technology have served as fundamentals for modern-day society, including architecture, energy, communication, and display technology. The possibilities with glass technology are unlimited. Contemplating what the future holds, some of Trajan's glass experts weigh in on where they see glass technology going.

Kyle Bachus PhD: General Manager – Precision Fluidic Systems (PFS) Business Unit

At Trajan, our motivation is always on improving the quality of analytical measurements, especially those in biological, environmental, and pharmaceutical applications/industries. We see a future where precision and accuracy in glass structures (such as quartz tubing) will become increasingly important for healthcare-based measurements, where subtle improvements can have a positive impact on a patient outcome. For this reason, our mission is to understand, design, and develop glass-based systems that reduce variation in analytical measurements with a focus on those in healthcare.

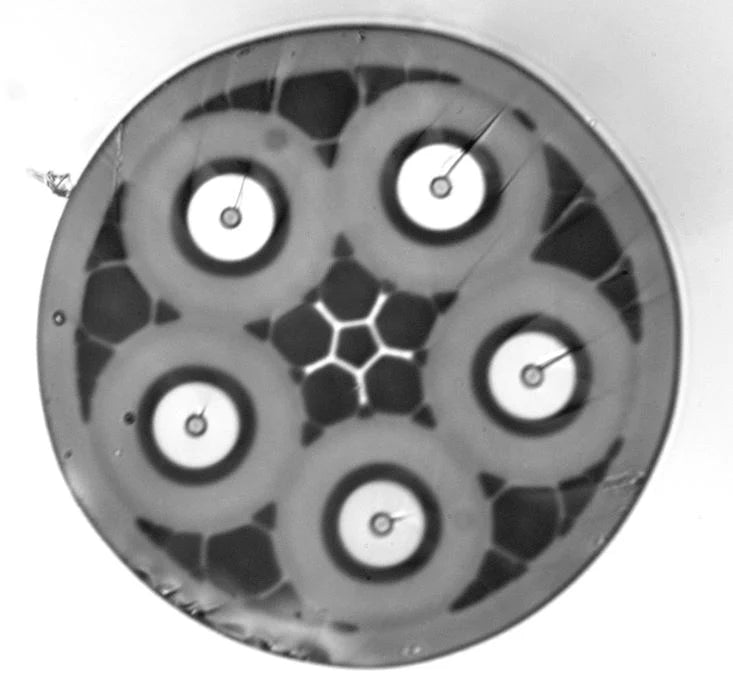

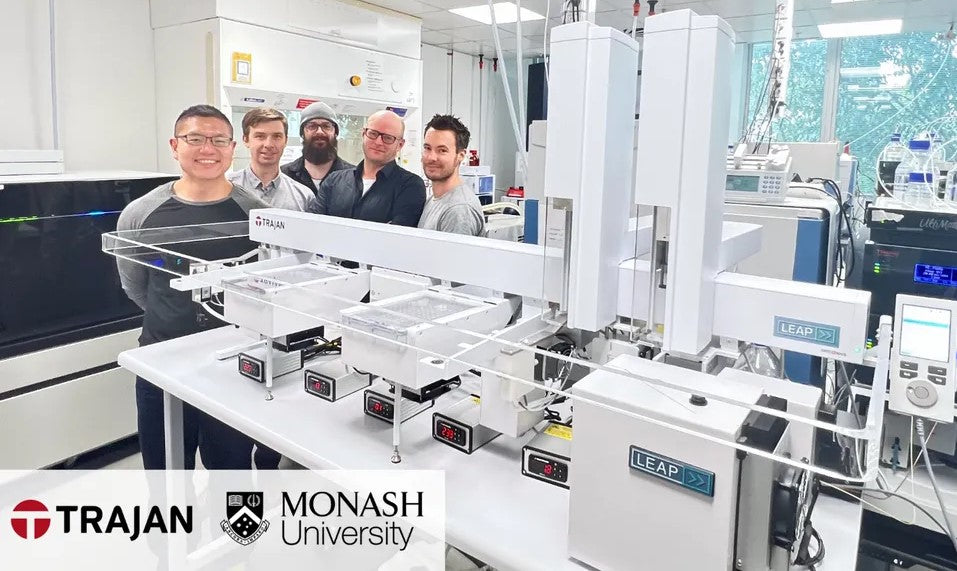

With this mission in mind, we actively collaborate with world leaders in glass technology within the academic and industry sectors, where we can bring some of the brightest minds together to solve real-world problems. An example of this is our collaboration with Dr. Younes Messaddeq at the Center for Optics, Photonics, and Lasers in Quebec City, Canada. Dr. Messadeq and Trajan have a shared vision to improve healthcare through new glass technologies. Specifically, this collaboration is investigating the potential application for a novel microstructured composite fibre to improve measurement accuracy as well as accelerate ‘sample to answer’ timelines and provide laboratories with greater throughput of samples.

Herbert Foo PhD: Principal Scientist - Glass Science

Like many other industries, the product development of the glass industry is moving towards using artificial intelligence (AI) and machine learning (ML) to assist and fast-track product design and formulation. These areas are what I am currently interested in and contributing to the organization in this direction. Glass will continue to be one of the materials of the future. Certainly, we will see more and more new products made from glass with novel properties. A key area of interest for me is to consider the advantages of glass-like surfaces on polymeric materials – how we control the surface of materials is key to managing the integrity of the samples we analyse.

Feng Li PhD: Lead Design Scientist

Fabricating borosilicate tubes into precision devices for the chromatography industry is a major part of our portfolio at Trajan’s Separation Science Business Unit. Glass is incredibly flexible and we are exploring new surface treatments and novel geometries to improve the performance of our existing portfolio.

What excites me is the progress of research in different fields of science and technology for developing future glass products. Generally, glass, especially high-purity ones, such as fused silica are notoriously difficult to shape, requiring high-temperature melting and casting processes. In recent years, 3D printing technology and injection moulding of fused silica has emerged and will be critical for developing the next generation of devices as this technology allows the creation of highly complex, freeform, or small-scale glass structures, which would be impossible without techniques such as 3D printing and injection moulding due to traditional manufacturing constraints. This is a research area of interest for me, and I’m working on bringing glass 3D printing technology to the organization for manufacturing new glass products with novel geometries and properties.

At Trajan, we believe glass has tremendous potential within the science, medical and biotechnology industries, enabling scientific solutions that benefit people.